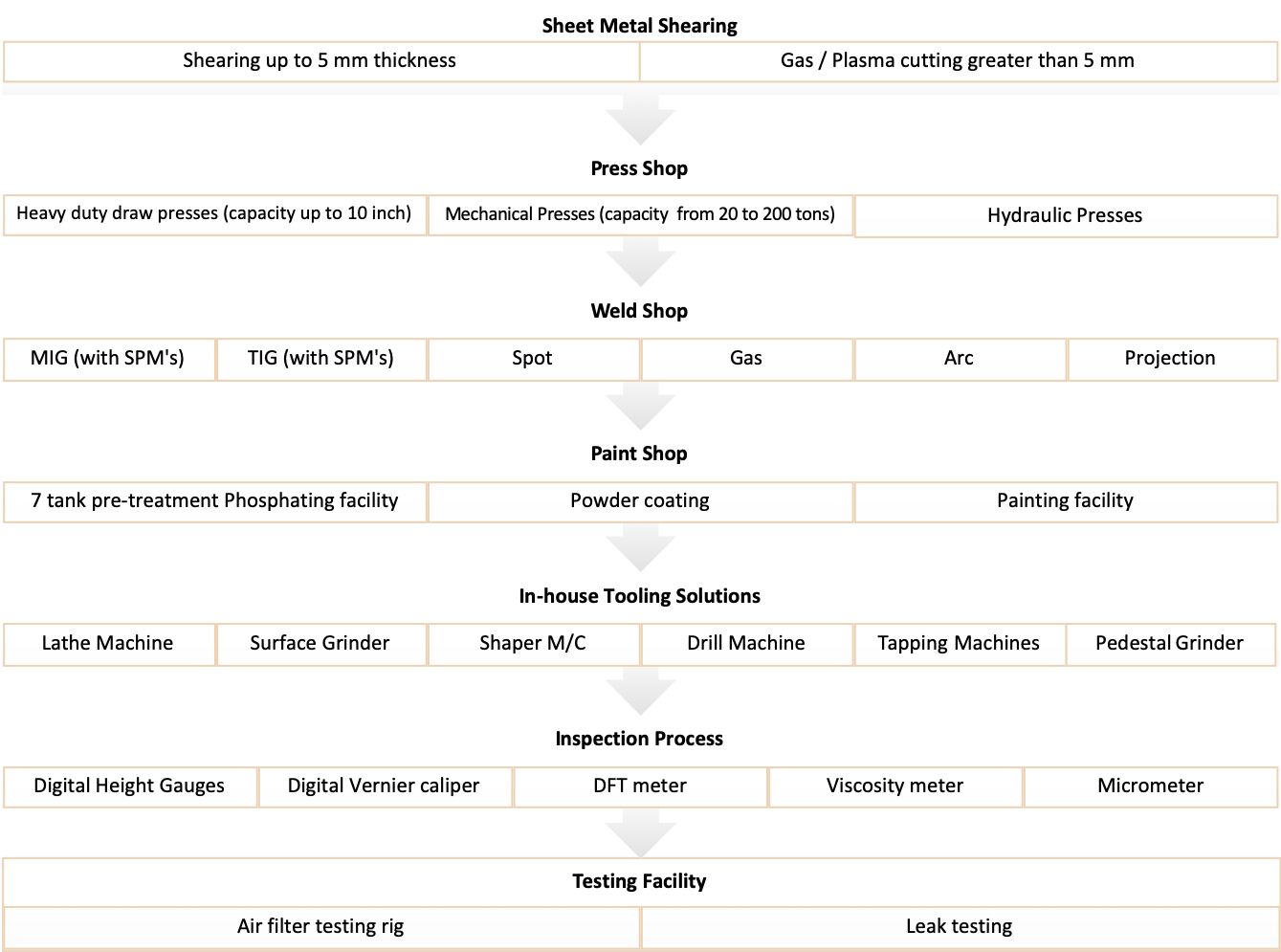

Infrastructure

From a mere coil of steel sheet to ready to install filters we do everything in-house with consciously sourced high quality raw material. Just like a highly refined well oiled engine we strive to maintain a synchronised production platform based on total quality management.

Our Capacity

Wet type air filter assemblies

20,000 per month

Oil filters

300,000 per month

Auto components

20,000 parts per Month

Sheet Metal Shearing

- Shearing up to 5mm thickness.

- Gas/Plasma cutting greater than 5mm.

- Leaser cutting for high precision components.

Press Shop

- Heavy duty draw presses (capacity up to 10 inch)

- Mechanical Presses (capacity from 20 to 200 tons)

- Hydraulic Presses

Press Shop

- Heavy duty draw presses (capacity up to 10 inch)

- Mechanical Presses (capacity from 20 to 200 tons)

- Hydraulic Presses

Weld Shop

- MIG (with SPM's)

- TIG (with SPM's)

- Spot

- Gas

- Arc

- Projection

paint shop

- 7 tank pre-treatment Phosphating facility

- Powder coating

- Painting Facility

paint shop

- 7 tank pre-treatment Phosphating facility

- Powder coating

- Painting Facility

Seaming

- Integrated Automatic Seaming Machine

In-house Tooling Solution

- Lathe MAchine

- Surface Grinder

- Shaper M/C

- Drill Machine

- Tapping Machines

- Pedestal Grinder

In-house Tooling Solution

- Lathe MAchine

- Surface Grinder

- Shaper M/C

- Drill Machine

- Tapping Machines

- Pedestal Grinder

Testing Facility

- Air Filter Testing rig

- Water Based Leak Testing

- Oil Filter Test Rig

- Impulse Test

- Vibration Test

- SST

- Burst Test

Inspection And Packing

- Digital Height Gauges

- Digital Vernier Caliper

- DFT Meter

- Viscosity Meter

- Micrometer

Inspection And Packing

- Digital Height Gauges

- Digital Vernier Caliper

- DFT Meter

- Viscosity Meter

- Micrometer

Injection Moulding

- Injection Moulding

- Metals Injection Moulding

Some of the facilities available with us include:

- Injection Molding Machines 150 Tons & 200 Tons

- Draw Presses with the capacity to draw up to 250mm

- Mechanical Presses 10 Tons to 200 ton, 20 numbers

- Hydraulic draw presses Capacity of draw up to 175mm

- Metal Inert Gas (MIG) welding

- Spot welding

- TIG welding

- Projection welding

- Arc Welding

- Brazing (gas welding)

- Pre Treatment plant for paint & powder component (7 Tanks)

- Powder coating and spray painting facility with 7 Tank Pre Treatment

- In House Tool Room (with four Lathe machines, Surface Grinder, Shaper Machine, three Drill Machines, 2Tapping Machines, Pedestal Grinder)

- Advanced Checking equipment (Digital Height Gauge Mitutoia, Height Gauge, four Digital Vernier calipers, Micrometers, Radius Gauges, Thread Go/No-go Gauges, Filler gauges, Angle protectors, DFT Meters, Viscosity Meters)

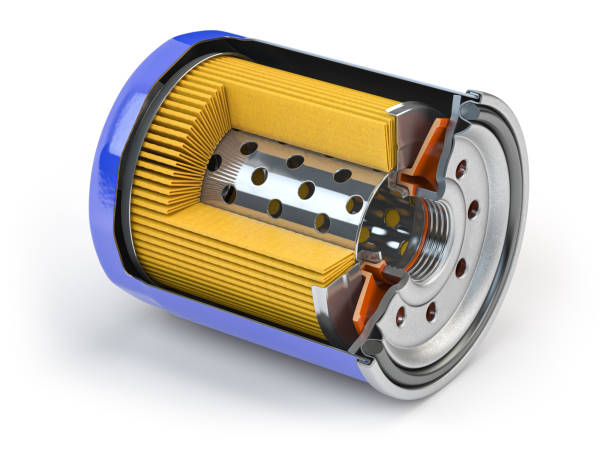

STRUCTURAL ANALYSIS

Bowl

- Manufactured in-house using powder-coated Cold rolled steel resistant to corrosion whilst protecting against mechanical damage.

Filter Element

- Out-sourced from only OEM level supplier's prescription tailored to match vehicle requirements

- Resistant to the aggressive chemicals and particles in today's synthetic oils

Pressure spring

- Optimum strength springs absorbs and dampens pressure pulses to maintain filter integrity

- Ensures position of internal components remain constant

Gasket

- Specially selected materials to ensure integrity and complete contact

- Resistant to both thermal and mechanical loads

Cover Plate

- Manufactured in-house using CR grade steel offering 20% more strength over HR grade.

- Precision engineered threads providing permanent connection of filter to the motor.

By-Pass Valve

- Maintains oil supply to engine even at low temperatures

- Precision engineered opening pressure to precisely match vehicle requirements

Subsribe To Our Newsletter

Stay in touch with us to get latest news and special offers.